Driven by the desire to always provide more efficient solutions and to answer our customers needs, Ceritherm developed a range of innovative equipment for industrial kilns and heat chamber.

Those equipment was designed to easily integrate on existing kilns for revamping/upgrading or new projects.

Ceritherm proposes:

Height saving kiln car (AER in French)

Height saving kiln car (AER in French) : Why kiln car fleet renewing would not lead to return on investment? Discover our innovative solution for height saving cars to increase production with the same kiln.

Height saving kiln car (AER in French) : Why kiln car fleet renewing would not lead to return on investment? Discover our innovative solution for height saving cars to increase production with the same kiln.

A range of gas burners

A range of gas burners required by your manufacturing process. The design is a real asset: burners fit to any type of configuration without modifications of your installations.

Learn More

MVIHT high-temperature integrated stirring systems

MVIHT high-temperature integrated stirring systems : The MVIHT developed by Ceritherm integrated to tunnel kiln roof, for instance, improve temperature homogeneity in kiln section by stirring, up to 900 °C. Waste due to « overfiring » and « underfiring » are drastically reduced as well as energy consumption.

Learn More

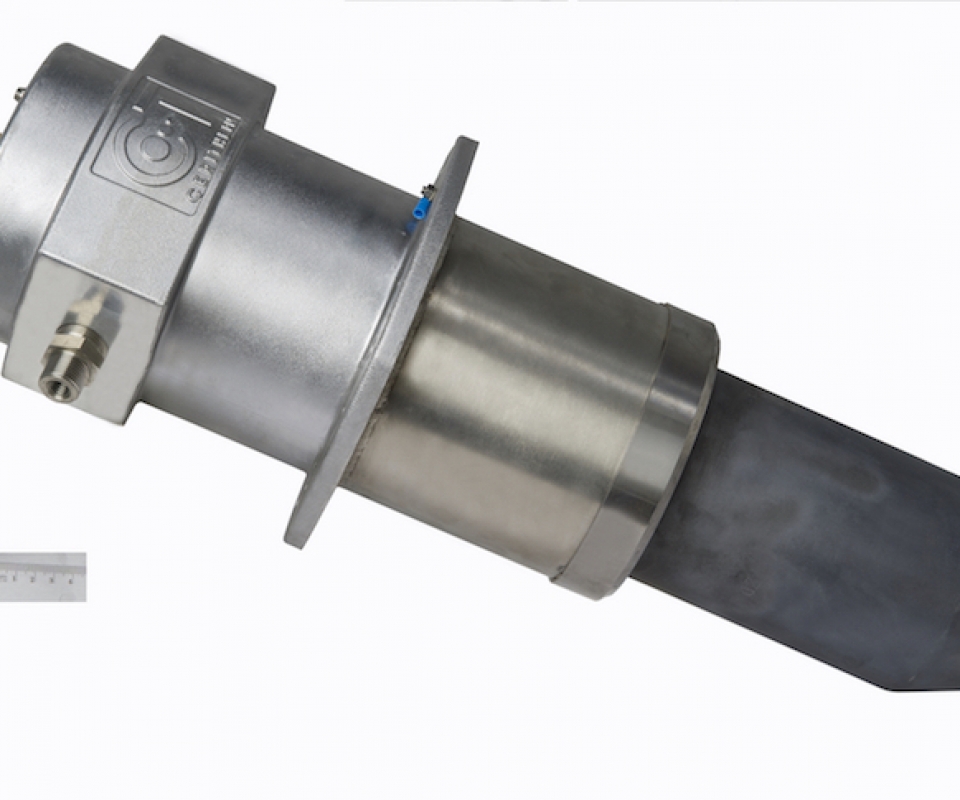

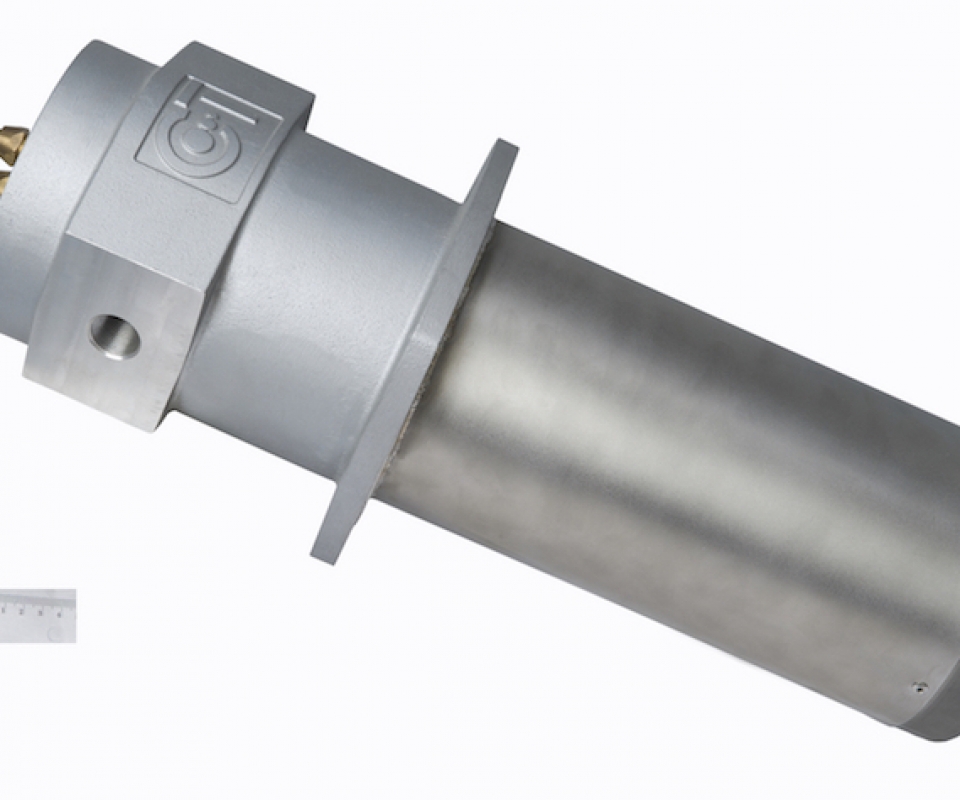

RADIAX® burner

RADIAX® burner is the first burner with flame position and power to be adjusted separately while operating the kiln.

Its patented distributor device stops or directs the airflow for radial or axial gases distribution in the kiln:

- radial injection for distribution near the burner nose,

- axial injection for long distance distribution

Learn More

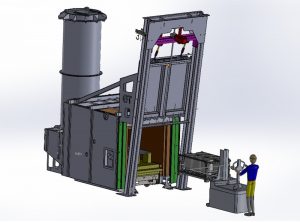

Sets of ultra-compact combustion set

Sets of ultra-compact combustion set : If compliance with air emission legislation was no longer a constraint! Thanks to an innovative design, Ceritherm post-combustion is very compact and has a compact design. To comply with standards of VOC rejection while recovering energy from your process.

Sets of ultra-compact combustion set : If compliance with air emission legislation was no longer a constraint! Thanks to an innovative design, Ceritherm post-combustion is very compact and has a compact design. To comply with standards of VOC rejection while recovering energy from your process.Learn More